Since the invention of the opposable thumb, the human species has worked hard using tools to improve their lives—the migration from migratory to sedentary lifestyles.

Since the invention of the opposable thumb, the human species has worked hard using tools to improve their lives—the migration from migratory to sedentary lifestyles.

Those living in one place discovered the need to build safe structures in which to live. Building materials varied as time marched on. Early buildings were constructed with thatch, then progressed to wood, rock, and adobe.

Eventually, metal elements were discovered, and people learned how to mold them as fabricated components. Around 2,000 years ago, metalworkers made a small, circular gold box by pressure welding the lap joints together.

The era of metal formation using welding began.

What is Welding?

Welding is a method of joining metals together to create or repair structures. The most commonly used fusion method is intense heat. Various ways of heating metal include an electric arc, open flames, or laser light.

Welding's Genesis

For nearly 1800 years, pressure welding was the only way to join metal pieces. Blacksmiths and farriers hammered iron into shapes for use as tools, horseshoes, and ornamentals. During the early 1800s, welding technology took a giant leap forward with Sir Edmund Davy’s discovery of acetylene.

Sir Davy experimented with the gas, and, using two carbon electrodes connected to a battery, created welding’s ubiquitous arc. However, 70 years passed before acetylene became used for welding. This method needed a suitable blowtorch to succeed.

Welding Evolution

In the following decades, advances in electrical current research directly applied to welding. The modern incarnation of welding is traced to one man, Augeste de Meritens. De Meritens used arc heat to join two lead plates together. Nikolai Bernardos, a Russian student of de Meritens, patented carbon rods for electric arc welding. Along with fellow Russian Stanislaus Olszewski, he patented processes in England and America using an electrode holder. This became the genesis of carbon arc welding using electricity as its power source.

Carbon arc welding uses an arc between a carbon electrode and the weld pool. The process is used with or without shielding or the application of pressure. The primary stated use was repair welding. The patent issued in 1885 to Augeste and N. Bernados notes the carbon welding process can be used for welding two metals, for severing and punching holes in metal. The patent described both a solid carbon electrode and a hollow electrode filled with powdered metals. Since they intended the powder to melt and flow to the weld, they are credited by some with inventing metallic arc welding. Ultimately because of the limitations of this approach, they are not credited with this accomplishment by most historians.

Carbon arc welding uses an arc between a carbon electrode and the weld pool. The process is used with or without shielding or the application of pressure. The primary stated use was repair welding. The patent issued in 1885 to Augeste and N. Bernados notes the carbon welding process can be used for welding two metals, for severing and punching holes in metal. The patent described both a solid carbon electrode and a hollow electrode filled with powdered metals. Since they intended the powder to melt and flow to the weld, they are credited by some with inventing metallic arc welding. Ultimately because of the limitations of this approach, they are not credited with this accomplishment by most historians.

In 1889, C. L. Coffin was the first to record melting metal using an electrode and carried it across the arc, depositing filler material inside the joint and finishing the weld.

Around that same time, a Russian, N.G. Slavianoff, used the same concept of transferring metal across an arc; however, he used this method for casting metal inside a mold.

The science and methodology of welding took off from here. The various weldments, accessories, and fuel improved and advanced leading up to the many ways of welding material together.

How Many Ways to Weld?

Although I’m sure there are many more ways of welding, I’ve discovered the following 24 methods, in alphabetical order:

| Atomic Hydrogen |

Indirect Spot |

Resistant Spot |

| Cross Wire |

Laser Beam |

Resistance Weld |

| Electroslag |

Magnetic Pulse |

Series Spot |

| Energy Beam |

Micro Resistance |

Single-Sided Resistance |

| Explosive |

MIG |

Stick |

| Flash |

MIG on 3D Printing |

TIG |

| Flux |

Plasma Arc |

Upset |

| Gas Tungsten |

Projection |

Vaporing |

Many of the methods listed are subsets of others, and writing about each would take up most of the internet's space.

Welding Series of Articles

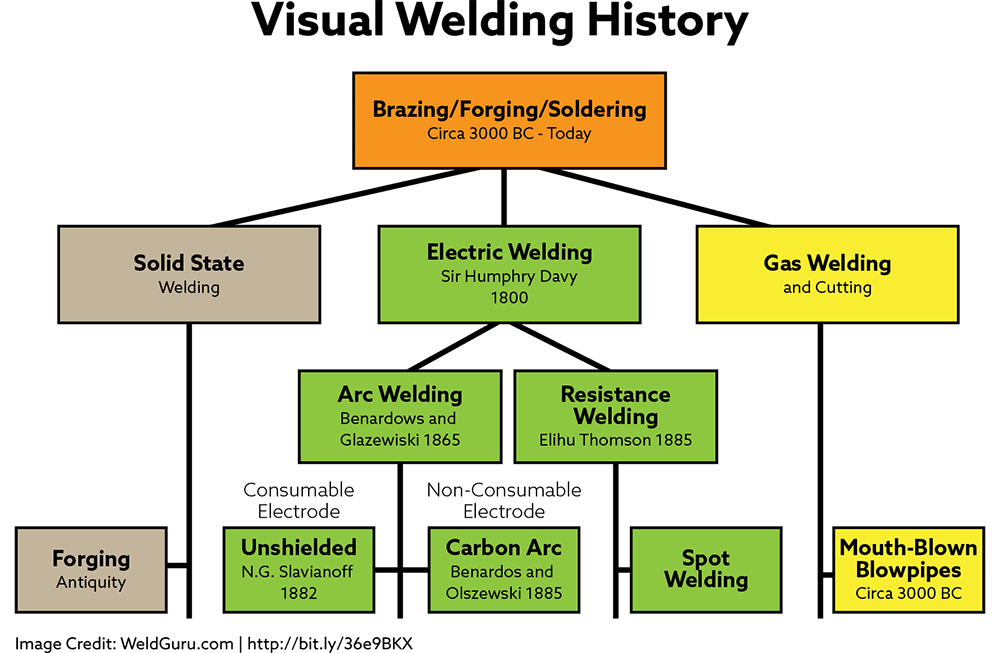

In the next series of articles, we present several welding forms using the illustration below as a guide. I hope you'll find them enlightening and informative.