For thousands of years, forge welding was the only welding game in town. Blacksmiths heated two pieces of metal until they were extremely hot and pounded them together.

For thousands of years, forge welding was the only welding game in town. Blacksmiths heated two pieces of metal until they were extremely hot and pounded them together.

The discovery of acetylene by Sir Edmund Davy in 1836 became the harbinger of change in welding methodology. Around the same time in Russia, Vasily Petrov developed the continuous electric arc. It took several decades, but after both these concepts merged, welding technology took off.

Contradictory Nature of War

In the early part of the 20th Century, manufacturing existed in a transitional period. Concepts and techniques taken for granted today were unproven then. Henry Ford's assembly line was new; updates to food industries were beginning for safety consumption, and forge welding was still the primary way of combining two metals.

In the early part of the 20th Century, manufacturing existed in a transitional period. Concepts and techniques taken for granted today were unproven then. Henry Ford's assembly line was new; updates to food industries were beginning for safety consumption, and forge welding was still the primary way of combining two metals.

One of the cruel ironies of history is how such a devastating event, destructive in nature, advances technologies that improve our lives. World War I was such an event. Up until the war began, ships were built with rivets, a process too slow for the ever-increasing demand for fleet development. Riveting wasn't just slow; it was massive! Ships built with rivets may weigh as much as 300 tons more, only from the rivets alone.

Gas Welding

Welding overtook riveting during the shipbuilding process because of improved speed and quality. Of the three welding techniques previously mentioned, gas welding jumped to the front of the line because of the limited technology available for arc and resistance welding. In addition to available technology, gas welding provided several advantages over other methods such as:

- The equipment is cheaper

- It can weld all types of metal

- Needs less maintenance

- It's portable

Despite these advantages, there were significant issues caused by gas welding: corrosion and brittleness.

Weakened Welds

Early in its history, somebody discovered issues during the gas welding process. Oxygen and nitrogen kept permeating the welds, which lead to excessive and way too much corrosion and excessive brittleness. These issues resulted directly in the welds' degradation and significant damage to ships, aircraft, and bridges.

After spending time studying the problem, atmospheric gases were discovered to be the culprit. When the metal is in a liquid state, the surface is extremely porous. Meaning, there's no barrier preventing atmospheric contamination. Harmful gases for welding include ones that make our world livable: oxygen, carbon dioxide, nitrogen, and water vapor.

Eliminating invading gases became a priority for welding. Researchers began looking into inert gas as a shielding agent against invading compounds using techniques perfected by chemists. During the 1920s, scientists began testing various gases and discovered that the Noble Gas Family provided the best shielding protection.

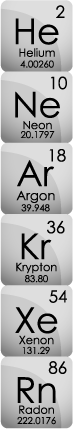

Noble Gases

Nobile gases occupy the far right of the Periodic Table. English chemist and physicist Henry Cavendish spent a great deal of time studying and researching various gases and calculating the Earth's density and mass. Cavendish focused on pneumatic chemistry, which led to a discovery he's famous for discovering what he called "inflammable air," or as we call it, hydrogen.

Nobile gases occupy the far right of the Periodic Table. English chemist and physicist Henry Cavendish spent a great deal of time studying and researching various gases and calculating the Earth's density and mass. Cavendish focused on pneumatic chemistry, which led to a discovery he's famous for discovering what he called "inflammable air," or as we call it, hydrogen.

It was during this work that he detected an unknown inert component of nitrogen, which he concluded,

If there is any part of our atmosphere which differs from the whole from the rest … it is not more than 1/120th part of the whole.

This discovery, however, was either forgotten or neglected for over 125 years. While studying the density of nitrogen in the early 1890s, Lord Rayleigh discovered that natural nitrogen, taken from the atmosphere, was denser than nitrogen created by chemistry.

Several theories tried explaining this difference; however, in 1894, Lord Rayleigh and William Ramsay showed that natural nitrogen was a mixture of nitrogen and a heavier, previously unknown gas. This new gas resulted in a new element, given the name "argon," because of its chemical inactivity.

Within six years, the other five noble gases had been isolated and identified.

The welding industry now had a means of protecting their welds.

Shielding Gas

Shielding gas is a gas blown down on top of the weld pool, creating an artificial atmosphere surrounding it. Its main job is protecting the weld pool from contamination from atmospheric gases such as oxygen, nitrogen, and hydrogen.

Most shielding gases are inert and stable under welding's extreme condition, so they're perfect in their shielding application. Depending on the gas being used, shielding gases also nurture the weld in different ways. Some shielding gases offer more fluidity; others offer better penetration; still, others offer smoother surface.

Welding Gases

There are two classifications of gases used in welding: inert and reactive. Inert gases are the nonreactive gases explained above. Reactive gases react with other elements or compounds. For purposes of this article, the focus is on the inert gases.

There are two classifications of gases used in welding: inert and reactive. Inert gases are the nonreactive gases explained above. Reactive gases react with other elements or compounds. For purposes of this article, the focus is on the inert gases.

Although only four noble gases are commonly used, there are ten gases in total available for welding.

Inert Gases

These gases are odorless, non-chemically, reactive, and colorless.

Argon (Ar)

Argon is the third most common gas on Earth, making it inexpensive to use. Except at extremely high temperatures, argon doesn't react with most substances. As a shielding gas, it's typically used with aluminum and stainless-steel welding applications. However, argon helps constant metal transfer from the electrode to the weld pool, improving arc stability.

Welding applications such as TIG welding are especially intolerant of oxygen and oxygen compounds, adopt argon, or helium, or both as their shielding gas. Nowadays, argon is usually preferred even in those applications because of helium's high cost and scarcity.

Helium (He)

Helium is comparatively more expensive than other noble gases because it's hard to produce, and there is limited availability on Earth. It improves heat input and provides deeper metal penetration, but arc consistency is difficult to maintain. However, when combined with argon, helium's starting inconsistencies improves considerably.

Helium Fact: helium doesn't freeze; it's possible to liquefy the gas, but not freeze it.

Semi-Inert Gases

These gases are used as a blend or pure. If the correct percentages are applied, they improve a weld's quality.

Carbon Dioxide (CO2)

Carbon dioxide is cheaper than argon, but you get what you pay for; reduced quality and increased spatter. Because of these deficiencies, carbon dioxide is usually mixed with other gases.

Oxygen (O2)

Oxygen is usually used in a mixture with other gases changing the fluidity of molten metal and improving welding speed. Mixing it with acetylene increases the heat in a flame high enough to weld steel.

Nitrogen (N)

Nitrogen is the most common gas found in Earth's atmosphere. Mixing it with other noble gases creates the opportunity for some specialized welding practices. Nitrogen works well with nitrogen-rich metals, but not carbon steel.

Hydrogen

Hydrogen is a very reactive gas—think Hindenburg. If used in small amounts, it's safe to use and increases the blend's heat.

Compressed Air

Compressed air is the cheapest noble gas. When mixed with other gases, it produces a stronger flame during lower temperatures compared to oxy-fueled flames. This allows welders greater control over the carbon coating's thickness applied to their welds.

The following gases are used in oxy-fuel welding and are violently flammable.

Acetylene

Acetylene

Acetylene is easy to produce and cheap to use. When combined with oxygen and used as a fuel source for certain welding types, it creates a flame hot enough to cut or weld most metals.

Propane

Propane is also known as Liquid Petroleum Gas (LPG), used as a fuel source, but it's dangerous because it burns exposed skin. Propane doesn't produce a reducing zone, so it's unable to be used in gas welding. Instead, it's used for brazing.

Propylene

Propylene is a blend of oxygen and burns much hotter than propane and oxygen. This attribute allows for non-structural fusion welding, heating, brazing, and more. Because it's supplied in disposable, small canisters, propylene isn't feasible for welding large items.

Shielding Gas Effects

In addition to creating an artificial atmosphere over a weld pool, shielding gases also affect the welding process in several ways. This includes:

Arc Stabilization: consistent welds with reduced spatter

Bead Profile Control: high carbon dioxide mixtures create a higher bead profile or convex, while argon controls the profile, making it flatter.

Penetration Rates: increasing carbon dioxide increases the heat into the weld pool, creating deeper penetration.

In Sum

The Chinese sage, Laozi, wrote, "The flame that burns twice as bright burns half as long."

In many ways, this adage applies to gas welding. Welding with gas became the first step away from forge welding. It provides mobility and the ability to work with metals that forge welding isn't able to.

However, as quickly as appeared, just in time to help shipbuilders during World War One, its use was overtaken by other welding methods.

Despite the advent of those other ways of welding, gas welding still is the primary method for various industrial sectors.

To me, the most curious aspect of this welding method is that it all began with one chemist's unexplainable test result.